Lost Wax Works: Where One-of-a-Kind Meets Mass Production in Jewelry Making

In its excellent article “Centrifugal and Vacuum Casting for Jewelry: A Step-By-Step Guide” the International Gem Society (IGS) tells us that the lost wax casting technique has been used for thousands of years across many cultures. “Closer to us in time, dentists in the 1940s used this technique to create pieces for dental work” which inspired many jewelers to use the technique to “create small jewelry settings.” Now entire pieces of jewelry are made using the technique.

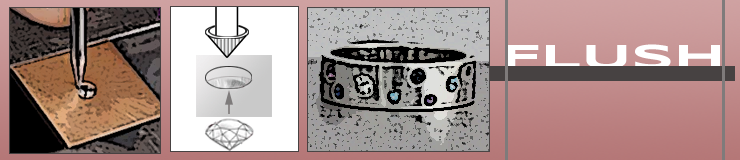

Special wax and sculpting tools allow jewelers to carve a piece of wax into a 3D “finished” model (sometimes referred to as a “pattern”) in preparation for having it cast in metal. Beginners may find an additional challenge in thinking of a design in terms of a reduction process (carving a piece from a block of wax) versus adding elements to a piece using traditional fabrication methods.

You can do the casting yourself but most people bring their patterns to a professional caster. The caster (I’m skipping some of the detailed steps here – see links to very detailed descriptions at the bottom of this post) will take your pattern and make a mold of it using a special plaster called “investment”. The plaster is now a reverse mold of your piece. After the mold dries, very hot (liquid) metal is poured into the plaster mold and your original wax model melts (is “lost”). The plaster disintegrates leaving you with a metal version of your wax model. You can now complete your piece using standard metal jewelry finishing techniques.

The technique is beautiful way to make a one-of-a-kind piece, such as an engagement or wedding ring, or create parts of a piece that will be attached to a hand-fabricated metal base. Ironically it also simplifies the mass production process, leaving you more time to focus on future design tasks.

Information & Resources

-

- Introduction to Lost Wax Casting — The Spruce Crafts

- Carving Wax — What to Do and Where to Get it — Stefan, Pembroke Historical

- Ganoksin Wax Carving Resources — Ganoksin Jewelry Making Resources

- 6 Reasons Why Wax Carving is Really Cool — Interweave, by Tammy Jones

- Studio Notes: Carving Wax with Kate Wolf — Interweave

- Wax carved jewelry images:

- Tutorials:

- Cut Loose — Wax Carving Basics Part 1 — Ganoksin

- Cuff Link Wax Carving Tutorial — YouTube

- 18ct yellow gold pinkie ring tutorial — Eva Dorney, Goldsmith

- Books & Media

- Book: Creative Wax Carving: A Modern Approach to an Ancient Craft with 15 Jewelry Projects — Emilie Shapiro

- Book: Lost-Wax Casting: Old, New and Inexpensive Methods — Fred R. Sias Jr.

- Video: Intro to the Flex Shaft — Metalsmith Essentials

- Video: Flex Shaft Essentials: Carve a Wax Model for a Pendant with Travis Ogden — Metalsmith Essentials

- Supplies/Tools: